The youngest Rolls-Royce turbofan developed 378 kilonewtons during the underground race in the English derby at the beginning of November 2023. This exceeds the thrust level that the UltraFan is designed for by six percent. According to Rolls-Royce, the initial phase of the test was conducted on 100 percent sustainable aviation fuel (SAF, in this case HEFA kerosene).

Rolls-Royce

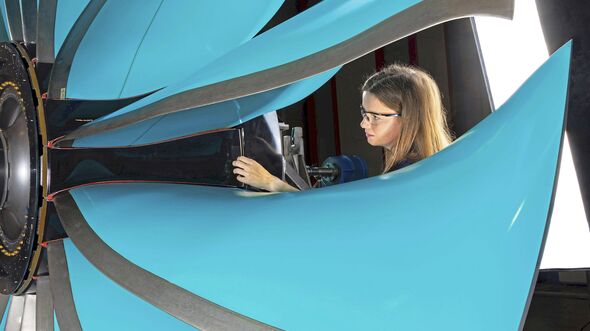

About a year ago, Rolls-Royce’s UltraFan demonstrator was brought to Testbed 80, which it claims is the world’s largest indoor test facility.

Climax and milestone

Testing on the new large inboard engine test bed at Derby, Testbed 80, is the highlight of a research and development program that officially began in 2014. The UltraFan UF001 demonstrator completed its maiden flight on April 24, 2023. Since However, the power has been gradually increased and the demonstrator has performed as expected, according to Rolls-Royce. Simon Burr, director of engineering and technology for Rolls-Royce, said at a press conference in June in Dahlewitz that about three tests take place a week. More than 70 hours of tests have now been collected.

Big fan, big gear

“This engine is unique,” Burr said. “It’s the biggest engine we’ve built so far.” The UltraFan has a fan diameter of 3.56 meters – 16 centimeters more than the world’s largest engine to date, the GE9X from GE Aerospace for the Boeing 777X. But not only about the size, but about the efficiency of the propulsion. A good indicator for this is the bypass ratio. It describes the ratio of the mass of air that is accelerated by the fan behind the primary engine to the mass of air that flows through the combustion chamber. According to Burr, the UltraFan has a ratio of 15:1. For comparison: the GE9X has a bypass ratio of 10:1, while the Trent XWB (Airbus A350) has a bypass ratio of 9.6:1.

Rolls-Royce achieves this thanks, among other things, to a reduction gear between the central pressure turbine and the fan. Rolls-Royce Germany and Liebherr-Aerospace developed the performance rendering and tested it on purpose-built test benches in Dahlewitz near Berlin. The engineers were not worried: during the tests, for example, the oil supply was interrupted and the performance of the bearings was examined. However, the manufacturer does not indicate how many gears have worn out during more than 650 hours of testing since 2017.

Rolls-Royce

Power transmission with a sun gear, five planetary gears and a fixed ring gear is an integral part of the CTi furniture made of carbon fiber and the titanium rim is also new.

Important part

Like Pratt & Whitney, Rolls-Royce relies on the planetary gearbox on the introduced turbofan (GTF) for the Airbus A320, A220 and Embraer 190-E2 and 195-E2. Rolls-Royce is silent on the ratio of reduction to weight, but the gearbox is a real colossus: It occupies an area of about one square meter and has a sun gear, five planetary gears and a fixed ring gear (the so-called gear) . planetary arrangement). During testing in August 2021, it delivered 64 MW of power – according to Rolls-Royce, this is a world record for aerospace. “Only” 51 MW of power is needed for the UltraFan, according to Burr. By comparison: A GTF planetary gear consists of a sun gear, five planetary gears, a ring gear and a fixed web, which is known as a star arrangement. It supplies up to 24 MW.

Focus on efficiency

The UltraFan is said to be ten percent more economical than the Trent XWB; Compared to the Trent 700 (A330), the fuel efficiency is said to be 25 percent better. In addition to the power transmission, the modified architecture – only two shafts instead of three – as well as a more basic engine with a higher pressure ratio of up to 70: 1 also contributes to this. To compensate for the extra weight of the gearbox, the large turquoise fan blades were made from a carbon fiber composite and given a titanium edge. The fan housing is also made of composite materials. The UltraFan is supplemented with a new ALECSys combustion chamber (High Low Emission Combustion System), which produces nitrogen oxides less than 40 percent (compared to the Trent 700) and almost no finer dust during flight. In addition, Rolls-Royce used new manufacturing processes to create the UF001, including modern cast connectors on the high-pressure turbine guide covers, which should also improve cooling conditions. New materials also went into the UltraFan, such as a sealing section made of heat-resistant ceramic materials (CMCs) for the high-pressure turbine, hybrid ceramic bearings and second-generation nickel superalloy discs.

Rolls-Royce

The UltraFan has a fan diameter of 3.56 meters, 16 centimeters larger than the world’s largest engine to date, the GE9X from GE Aerospace.

The future is uncertain

After a recent full strength test, the performer will now be thoroughly inspected. It is unclear what will happen next. “When we finish this test phase on the UltraFan, we will suspend the entire engine demonstration program until one of our aircraft customers is ready to use this new engine design,” Rolls-Royce CEO Tufan Erginbilgic said at an event in Derby. in mid-May he announced to celebrate the first run of UltraFan. The UltraFan is Rolls-Royce’s first fully redesigned engine since the Trent XWB, which completed its first run in 2010. In the end, only one demonstrator was built, not four as planned. “It’s an incredible eight to 10-year effort. It’s a huge responsibility for all the people, institutions and government investments involved to deliver the engine as promised,” said Burr. UltraFan was intended to be the successor to the Trent family for many people. But there is no new aircraft program on the horizon at Airbus or Boeing in which such a large turbofan would be an option.

However, Rolls-Royce insists that the UltraFan can be reduced to a thrust of between 110 and around 490 kilonewtons. The lower part meets the requirements of conventional aircraft such as the Airbus A320 or Boeing 737 or their successors, which are expected for the 2030s. “If you start big, you can scale back by doing research across the board,” Burr said. Research is also ongoing to improve the technology. In the HEAVEN project (Hydrogen Engine Architecture Virtually Engineered Novelly) of the European space research program Clean Air Transport, UltraFan is further developed for short and medium-range aircraft, for example, with the addition of hydrogen and hybrid-electric technology. The project has been running since the beginning of 2023 under the leadership of Rolls-Royce Germany and will be supported by the EU Commission with around 30 million euros until the end of 2026. The development of the Ultra Fan has already been financed by the European initiative Clean Sky 2, the initiative of German LuFo and the British government.

Rolls-Royce

Currently, the focus at Rolls-Royce would not be to put new engines into service, but rather to allow the technology to mature.

Mature technology

Retrofits of existing aircraft, for example A350 or A320, are currently not an option. “What (The UltraFan) would look like an engine on an airplane is driven by a platform. And it will be the platform of the future,” said Rob Watson, President of Civil Aerospace at Rolls-Royce, in June Dahlewitz. The goal at the moment is not to put new engines into service, but rather to allow the technology to mature. Even if the UltraFan isn’t currently in use on the plane, Rolls-Royce has some features in mind that could find their way into the current Trent engines. This includes new materials and manufacturing processes for the high-pressure turbine as well as seals and bearings for the hot end (the areas of the engine from the combustion chamber). New alloys of turbine discs and blades are planned to be introduced in commercial turbofans as early as 2025.

Economical gas turbines

“The gas turbine is an amazing machine that converts energy very efficiently,” Burr said. We will continue to invest in making it better. Burr attributes the gas turbine to a key role in climate-friendly flight: “We estimate that a combination of the latest generation gas turbines such as the UltraFan, powered by 100 percent SAF, will make up about 80 percent of the solution total by 2050 to reach zero aircraft operations (…).”