Mitsubishi Electric robots with ESD certification have several differences compared to conventional models that allow the components to be protected against any sudden leaks that could affect the final product.

Mitsubishi Electric presents a new version of the MELFA robot family designed to meet the needs of the electronics market. These robots are ESD certified and clean room certified.

and Lucia Quaglietta

Mitsubishi Electric introduced a new version of ESD for the family robot MELFA ability to work in an environment with a risk of electrostatic discharge. Inside of’electricity sector events related to electrostatic discharge (ESD) can be very harmful to production and workers.

The law of reference in this area is IEC 61340-5-1, which governs the necessary requirements for the handling of discharge-sensitive products. Some of the factors that cause the development of ESD are working in the environment and electric field above 100 V/cm, low relative humidity (<20% RH) and low temp. Moreover, even large areas of contact during handling can lead to the formation of friction charges (triboelectric charge).

ESD CERTIFICATE

The Mitsubishi Electric robot is equipped ESD certification they present some differences compared to conventional designs that allow the components to be protected against any sudden leaks that could affect the final product.

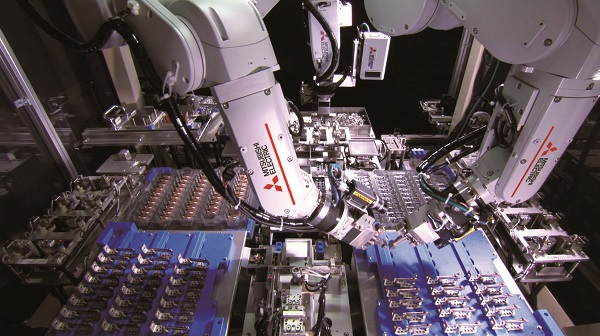

The ESD robot version is ideal for all types of applications involving the manipulation of printed circuits e electronic boards: PCB and connector assembly, component inspection, board and circuit testing, electronic component installation, electronic board soldering.

The ESD version of MELFA robots is ideal for all types of applications involving the manipulation of printed circuits and electronic boards.

CLEAN ROOMS CERTIFICATE

These robots also have clean room certification (ISO Class) issued byFraunhofer Institute IPA, the certification body for this type of control. This is the most requested certificate in the electricity sectorwhere tests are often carried out in a clean room with forced air circulation to prevent microparticles from contacting the product and contaminating it.

WORKS RELATED

Inside of electricity market there are very demanding requirements in terms of accuracy, performance and communication.

To meet those market needs, the option can be combined MELFA Smart Plus, a card that enables functionality that significantly increases machine accuracy by compensating for the robot’s internal temperature. To support the most demanding activities take a look A power sensor is available and integrated AI functions which increases space and speed parameters.

The MELFA Smart Plus function is part of the brand MAISART (Mitsubishi Electric’s AI creates Advanced Technology), a separate brand developed by Mitsubishi Electric with the aim of enabling the company to gain greater profits fromartificial intelligence.

Cooperation, safety and intelligence are the pillars on which the robotics proposed by Mitsubishi Electric are built.

INCREASE PERFORMANCE

Additionally, to increase functionality, robots are often associated with a rotating table, in which individual elements are placed that are later collected by the robot itself when the table rotates. To upgrade the configuration, the ruler of Mitsubishi Electric robots has a special integrated work which allows you to manage up to eight acres without using additional equipment.

They are available special examples which have a cable route completely inside the hand – to the wrist of the robot – thus avoiding interference mechanics during operation.

Family robots MELFA FR ESD are also available in a linked version and PLC the season MELSEC iQ-Rwhich thanks to the SECS/GEM communication protocol (the standard protocol in the semiconductor world) allows better monitoring and sharing of the collected data.

Finally, the duties of controller CR800 makes the robotic movement possible with response times of 3.5 ms through the use of customized interfaces. ©TECNeLab

ESD certified MELFA robots are suitable for PCB and connector assembly, component inspection, board and circuit testing, electronic component assembly and electronic board soldering.