Japanese Mazda cars have long been the only ones to use Wankel rotary engine technology in their cars. At the end of 2023, the car manufacturer put on the market, for the first time in more than a decade, a new car using this technology. Why then restart the rotary engine in the electric age?

The rotary engine makes its first hybrid

Recently, Mazda released a new car with a rotary engine, the first since the RX-8 ended production in 2012.

MX-30 e-Skyactiv R-EV, launched on the market in November 2023. (© Mazda)

Instead of using its rotary engine to drive the vehicle directly, the MX-30 R-EV uses it to power a generator. The electricity generated is then used to power an electric motor, in a configuration known as a “series hybrid” or “long-range electric vehicle”. Some vehicles have already been developed in this fashion, notably in the Nissan e-Power and Honda e:HEV ranges (which this system can also drive all-wheel drive).

What sets the MX-30 RE apart, however, is that unlike the e-Power and e:HEV, it doesn’t have a reciprocating engine (which relies on reciprocating pistons to generate power), but an output. Wankel rotary engine (which produces power by rotating a triangular rotor). And with its plug-in hybrid unit with a high-capacity battery, the MX-30 R-EV can also be used as an electric vehicle only.

There is a reason why Mazda chose to add this technology to the MX-30 R-EV: while environmental concerns are increasingly present among manufacturers, rotary engines are not suitable due to their fuel consumption and their high hydrocarbon emissions. These restrictions sealed the fate of the technology, and in 2011, Mazda was forced to stop production of rotary engine cars.

In 2013, Mazda discontinued production of the RX-8, making it the last sports car to feature a rotary engine. (©Mazda)

Now, Mazda has managed to improve the engine’s fuel efficiency and carbon dioxide emissions by combining it with a plug-in hybrid unit, and the car is now ready for sale. But why does Mazda want to bring circuit technology back to the circuit this time?

Some dental problems

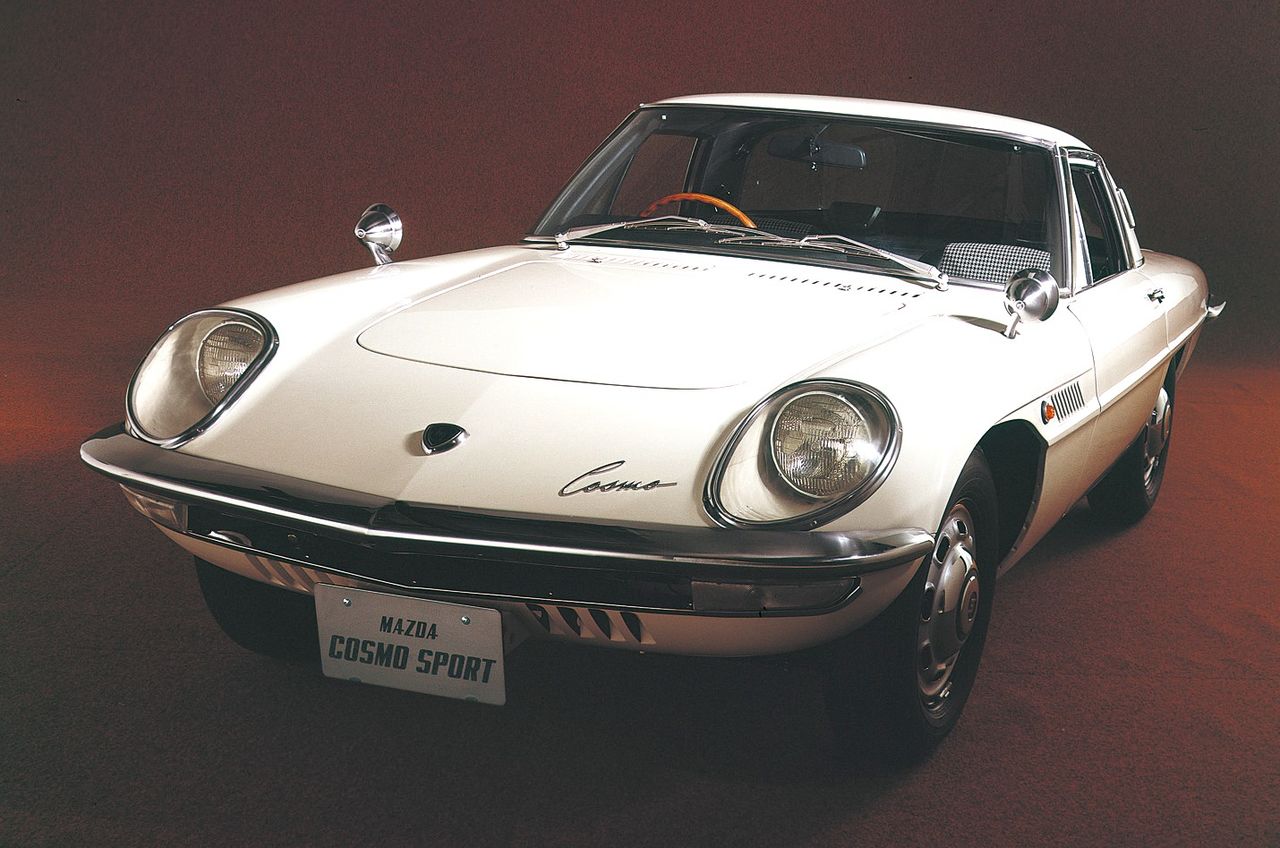

In 1967, Mazda began mass production of rotary engines (then called “engines of the future”) with the Cosmo Sport, which was the second such car to be mass-produced after the NSU Spider (launched on the market in 1964 by the German manufacturer NSU).

Through an agreement concluded in 1961, Mazda acquired the basic technologies developed by NSU, which at that time was the pioneer of this type of engine. And unlike the German manufacturer, which quickly stopped production of the engine following several problems, Mazda overcame many obstacles to produce cars using this technology and distribute it worldwide for almost half a year. In addition, NSU and Mazda are the only manufacturers that have mass-produced this type of car, and therefore, the Japanese car manufacturer is the only one in the world that has been able to successfully sell rotary engines.

At NSU they were generally called “Wankel engines” (after the name of their inventor), but in this article I use the term “rotary engine”, which is recommended by Mazda.

The futuristic design of the 1967 Cosmo Sport was featured in the film Return of Ultraman. (©Mazda)

Let’s look at the challenges Mazda faced in bringing its rotary engine to market. In the past, the biggest problem was vibration marks: ripples or wear that appear in the rotor housing (similar to cylinders in a rotary engine) over time. In order to overcome this problem, Mazda came up with the idea of making seals on the combustion chamber from self-coating carbon material, developing new lubrication methods in collaboration with manufacturers, and using hard chrome coating for the interior. Mazda was also the first to adopt computer analysis in 1963 to find the causes of internal vibrations associated with the brand.

Thus the company has acquired a wide range of expertise in materials, surface treatment, and vibration and combustion analysis, thus laying the foundations of its world-class technology. In addition to allowing Mazda to improve its technical skills, the rotary engine also played an important role in allowing the manufacturer to flourish, gradually becoming the powerful car manufacturer it is today.

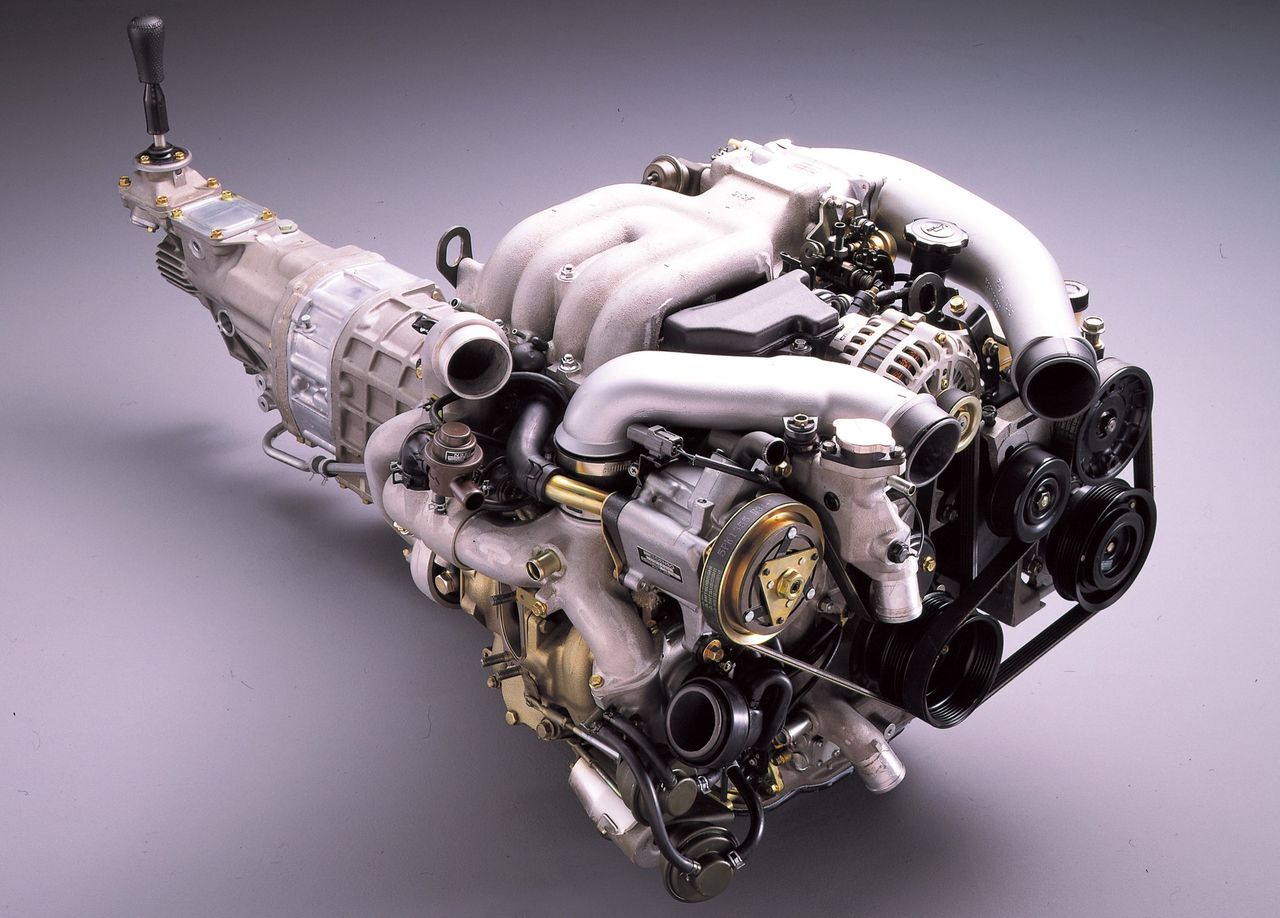

The rotary engine of the 1991 RX-7 includes a twin-turbo system that allows it to reach 250 horsepower in a compact package. (©Mazda)

In the 1960s, Japan considered reorganizing its automobile industry into three main groups: mass production, luxury cars, and light cars. Mazda, then called Tôyô-kôgyô, entered this market in 1960 with a series of lightweight models. So forced to join the third group, the company did not see it that way. Its engineers, driven by the vision of a multi-skilled brand, relied on the company’s proprietary technology to prove their skills, and especially on the rotary engine.

This strategic choice, beyond its technological importance, was decisive in the rise of Mazda as a car manufacturer, despite the abandonment of the government’s project to reform this industry in the face of its rapid expansion in Japan.

The future of the rotary engine

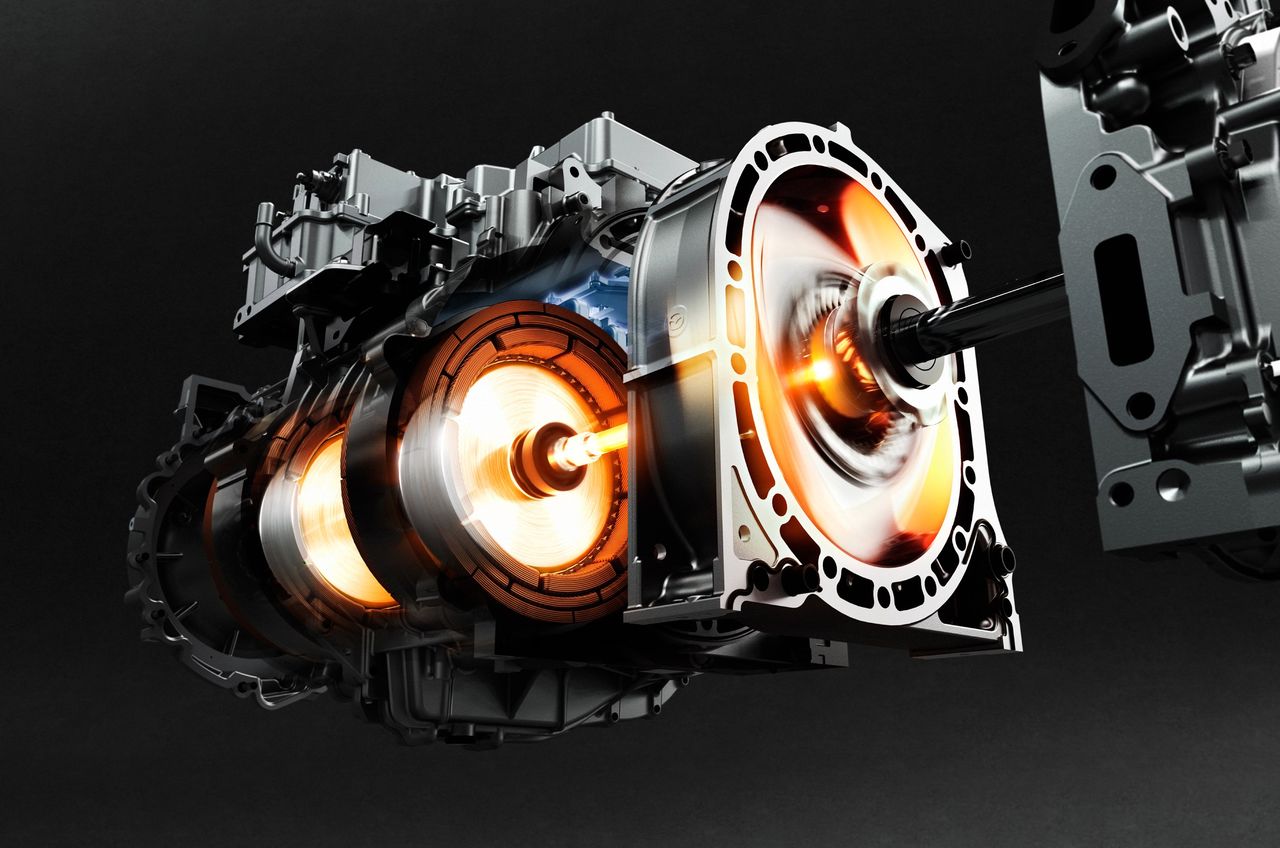

For its 2023 MX-30 R-EV model, Mazda not only combined a rotary engine with a hybrid configuration, but also modified it significantly to improve its energy efficiency and environmental performance. Therefore, the company has integrated a direct injection system to improve the accuracy of its fuel distribution, thus reducing consumption during cold start phases, but also modified the interior of the combustion chamber, to speed up its procedure and increase its effectiveness. In addition, the engine has lost 15 kg due to the use of an aluminum side casing, and its durability has been enhanced by the use of a ceramic coating of thermal spray in it.

This new rotary engine, called “8C”, represents real craftsmanship. It is equipped, to use the terminology of similar engines, with a redesigned cylinder block, cylinder head and pistons, until we can talk about a total renewal of this technology.

In the MX-30 e-Skyactiv R-EV electric vehicle system, the compact car already shares a common axle and generator. (©Mazda)

Despite its progress, the MX-30 R-EV boasts a fuel efficiency of 15.4 km per liter (as measured in WLTC mode), which remains below expectations. Although it does not have a direct competitor in the market to make a fair comparison, however we can note that the Toyota RAV4 plug-in hybrid achieves 22.2 km/l, while the Prius plug-in hybrid shows 26.0 km/l. Therefore, the MX-30 R-EV lags behind in terms of fuel consumption.

The future of the rotary engine, even associated with the plug-in hybrid group, is therefore not yet guaranteed. Mazda, however, strives to maintain its interest in the market by making it more attractive, not only by improving its fuel efficiency, but also by ensuring that its cars retain the beauty and proper performance of the brand. The rotary engine is truly an integral part of Mazda’s identity.

During the presentation of its “Iconic SP” concept car at the Japan Motor Show in autumn 2023, Mazda demonstrated the potential of this technology by presenting a stylish sports car with a twin-rotor engine, which represents a true evolution compared to one. MX-30 R-EV rotor model. With the launch of the MX-30 R-EV, Mazda has demonstrated its determination not to let the rotary engine die. Let’s hope this promise will continue to be fulfilled in the future.

(Header photo: the triangular rotor of Wankel’s MX-30 e-Skyactiv R-EV engine inside a cocoon-shaped frame. It delivers its power through rapid cycles of compression, ignition and exhaust. © Mazda)